Instructions for the Grabcad Print software we are using on our Stratasys uPrint SE Plus.

The model we are using is a .stl-file, other file format will work, but for the most, .stl is the most used for 3D-printing

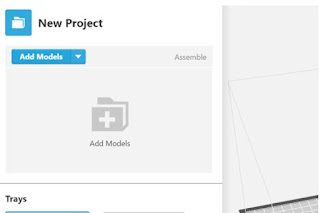

After you started the software, you need to add your model to the print software.

Just click Add Model and choose.

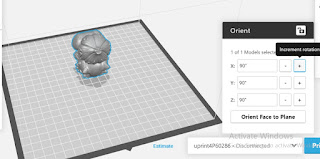

The Grabccad software will now place the model quite random, in this case, the model are made to have the right side down, not all model do this

If the model do place itself wrong, use the orient tool to put it as its best on the tray.

You can choose different angles that fitts your model

One option is to "orient face to plate", choose and click the face that will be at the bottom

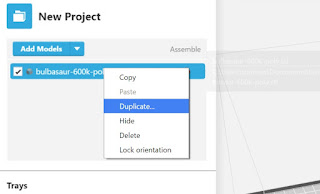

In case you want to print out more then one model, right click on the model and choose duplicate, add a value.

If the number of model makes the total larger then the tray, Grabcad makes a new tray/plate automatic

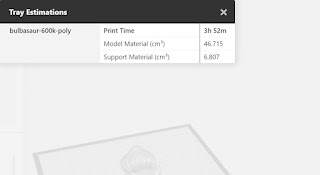

Befor start the printing, check the estimate (down in the middle)

That will show you the print time and amount of material used

Timelaps of the printing

Printer specific settings and setup, too much to add now, but who knows :)