Simulating with Millplus IT PC-software, WinXP only

There is a simulation/computer software for the millplus IT v530.

It use to be on the www.millplus.de webpage when it was alive.

It's a freeware without saving capability. Ask, I may give it away.

so for the closest mourners, simulate millplus on a PC

A video of some demo I made few years back:

Use a virtual machine with winxp, install the millplus

software.

Without a physical Dongle, no saving is permitted.

Theres possibility to sideload a CNC-program, and simulate

it.

You can make your own program in ISO and IPP, but not save.

Use the overlay-file to see the machine-button-command.

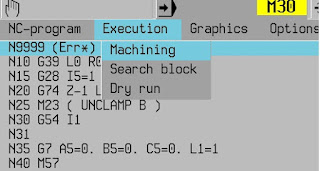

Menu items are in the upper gray field click to open, but

the are not clickeble in its own, use arrow keys on the keybord, enter to chose

Startup

You need to run the reference point before anything can be done, by clicking the ”all

axis”-button.

Start cycle with CTRL+F8

Now the machine is ready to use.

Place a millplus compatibility CNC-program in the Work-folder,

prgnr.pm

Open the program in the same manner you do in the real machine

You may edit and program, but, no saving!

Running a simulation.

When you are in the machining view, chose your program to

load it. tap the menu row, and move with arrow-key

You can run the CNC-program here, but the syncron graphic is

zoomed out too much to make a good use,

more on this later

Go to the Menu-field, use arrows to go to graphics, point down

to wire plot, enter

Now you can start the machining by use CTRL+F8 (CTRL+F7 to

stop, F10 to clear)

You need too fix the zoom level if you don’t use G98/G99 after

starting the machining the first time.

The scale is out of bounds, use the scale buttons to get a

nicer zoom lever, note, Z is still out, havent figure it out yet

The 2nd time you run the machining it will be watchble.

You can use G98 and G99 to make a workpiece and run it in "full 3D" if needed.