Blogging about the following awesome things: CNC, CAD/CAM, machining, 3d printing, fanuc 21, siemens sinumerik, siemens 810D, siemens 840D, Siemens 840D sl, Stratasys, Grabcad print, NX, fusion 360, instruction videos, apps

Tuesday, December 8, 2020

NX, right plane (CSYS) from the start, manufacturing

Wednesday, October 14, 2020

Engraving on mantle surface on a round detail Siemens Sinumerik 840D sl

Engraving on the radius surface on a round detail

Prerequisites in

the program is adapted to TRACYL execution:

Check https://cnccodinguide.blogspot.com/2019/05/drillmill-on-diametric-part-of.html

The simulation

program's tool spindle is called 3

The value after

TRACYL is the diameter of the part, in this case, diameter 70

The cycle should

be run in G19 plane

The zero position

of the cycle is changed, e.g. X is the same as Z (depth of milling), then from zero that

sits in the center (differ from the pocket cycles there) X1 is cutting

depth, Y position on the arc, Z is the same as usual

The simulation shows mirrored text, therefore uses mirror writing

Tool "countersink"

Finished program:

Friday, May 8, 2020

thread milling inside or outside without special tools

do not got the mill tool?

got a lathe/turning machine?

with a smaller thread turn tool, a boring tool actually.

This tool needs to be a tool for internal lathe, and then we go

as always, show the pic of the tool, this one is from indiamart.com, othervise sandvik

month the tool in you mill chuck and you're on the go

check the video after the instructions..

Chose an internal tool, called ..:

Thursday, February 27, 2020

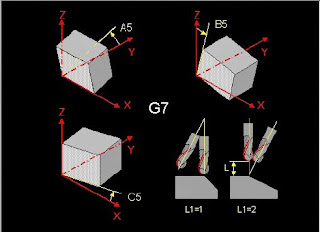

Heidenhain Millplus IT and Tilting the coordinate system in autodesk Fusion 360 CAM with G7

Heidenhain iTNC530 should be on the same principle as Cycle 19

In the CAM-system, when you are about to tilt the work plane for 4-5 axis machining, you need to use the right tool-coordinate system to make this work.

I use this rule to tilt the coordinate system:

In this case, we will use A5=90, A5=-90 for the Y sides, B5=90 and B5=-90 for the X sides to cover all the sides

All the facts of the CAM in fusion:

Use the pen-shaped button on the upper left.

Find setup1 and setup1 again and the 4 drilling operations but you will not see the tool coordinate system, only the tiny marking for the tool position, Download and use your Fusion 360-program to check this out

We have now a totally 5 coordinate system to juggle with, nice..

The CNC-code:

N1001 (1001)

N10 (T1 D=10 CR=0 TAPER=118deg - drill)

N11 G90

N12 G94

N13 G17

N14 G71

N15 G99 X-10 Y-10 Z-61 I72 J72 K71

N16 G98 X0 Y0 Z-51 I52 J52 K51

N17 G74 Z0 L1

N18 (Drill1)

N19 T1 M6

N20 S5000 M3

N21 G54

N22 G7 A5=0. B5=-90. C5=0. L1=1

N23 M8

N24 G0 X-17.351 Y26.224

N25 G0 Z15

N26 G17

N27 G0

N28 G0 Z5

N29 G81 Z-5 Y5 B1 F1000

N30 G79 X-17.351 Y26.224 Z-1

N31 G0 Z15

N32 G74 Z0 L1

N33 (Drill2)

N34 G7 A5=90. B5=0. C5=0. L1=1

N35 G0 X25.112 Y-14.595

N36 G0 Z15

N37 G0

N38 G0 Z5

N39 G81 Z-5 Y5 B1 F1000

N40 G79 X25.112 Y-14.595 Z-1

N41 G0 Z15

N42 G74 Z0 L1

N43 (Drill3)

N44 G7 A5=0. B5=90. C5=0. L1=1

N45 G0 X17.687 Y24.823

N46 G0 Z67

N47 G0

N48 G0 Z57

N49 G81 Z-5 Y5 B1 F1000

N50 G79 X17.687 Y24.823 Z51

N51 G0 Z67

N52 G74 Z0 L1

N53 (Drill4)

N54 G7 A5=-90. B5=0. C5=0. L1=1

N55 G0 X24.699 Y18.413

N56 G0 Z67

N57 G0

N58 G0 Z57

N59 G81 Z-5 Y5 B1 F1000

N60 G79 X24.699 Y18.413 Z51

N61 G0 Z67

N62 M9

N63 G74 Z0 L1

N64 G7 L1=1

N65 M30

Often, I do not use an edge finder and a bottle of windows cleaner when I'm milling, trust me on that :)